|

|||||||||

Air Amplifiers - Use Compressed Air Efficiently for Venting, Exhausting, Cooling, Drying and Cleaning |

|||||||||

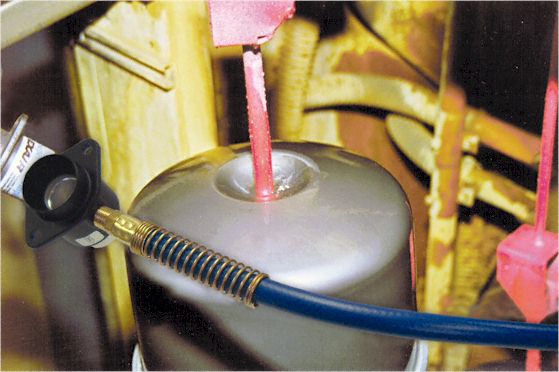

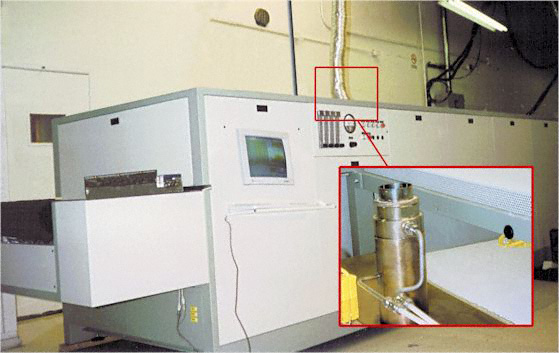

What is an Air Amplifier?Air Amplifiers are efficient air movers that put the surrounding ambient air to work in order to solve common industrial problems. Air Amplifiers can be used to vent welding smoke, cool hot parts, clean machined parts, distribute heat in molds/ovens, ventilate confined areas, exhaust tank fumes and wipe hose, wire, and fiber optics. Air Amplifiers pull in large volumes of surrounding room air to create output airflows that are up to 25 times that of the compressed air consumption rate, while still being quiet. The airflow and velocity of an Air Amplifier are infinitely controllable. Large or small volumes of air are easily obtained by controlling the amount of compressed air usage with a pressure regulator. |

|||||||||

Air Amplifiers versus BlowersSimple and low cost Air Amplifiers offer distinct advantages over blowers and fans. Energy conscious plants might think a blower to be a better choice due to its slightly lower electrical consumption compared to a compressor. In reality, a blower is an expensive capital expenditure that requires frequent downtime and costly maintenance of filters, belts and bearings. Air Amplifiers offer the following advantages:

|

|||||||||

To learn more about Air Amplifiers, choose one of the following:Super Air Amplifier - Patented Super Air Amplifiers provide higher efficiency than ordinary air movers. Adjustable Air Amplifier - In both aluminum and stainless steel, the Adjustable Air Amplifier can be adjusted to fit your specific application. |

|||||||||

Copyright © 2023 - EXAIR LLC. All rights reserved. |